We’re excited to share the following article by Mischa Bijenhof for Bouwmachines, which covers QuinteQ’s innovative flywheel energy storage system and the collaboration with construction company BAM and crane company Van der Spek. You can read the original article in Dutch here, or read on for the English version.

The future of construction sites: Tower cranes and ‘kinetic batteries’

The new Dutch company QuinteQ Energy is developing a kinetic battery, which has already been tested at a BAM construction site in Amsterdam.

Flywheel technology as a solution for construction.

A construction site full of electric machines, but without containers full of batteries: it may seem impossible, but it can be done. QuinteQ Energy, a Dutch startup based in Culemborg, uses aerospace technology to make it a reality.

In the search for the construction site of the future, numerous possible solutions are being explored. Hydrogen, wind, or solar energy are used to generate electricity—sometimes on-site—while biogas, e-fuels, and hydrogen can serve as alternatives to diesel in specially adapted combustion engines. The latter option will never be entirely emission-free, while all-electric options require large batteries that are expensive, maintenance-intensive, and not very environmentally friendly to produce.

There is another way to store energy: in a flywheel. This form of kinetic energy storage does not rely on chemical processes and therefore contains no harmful substances.

Energy revolution

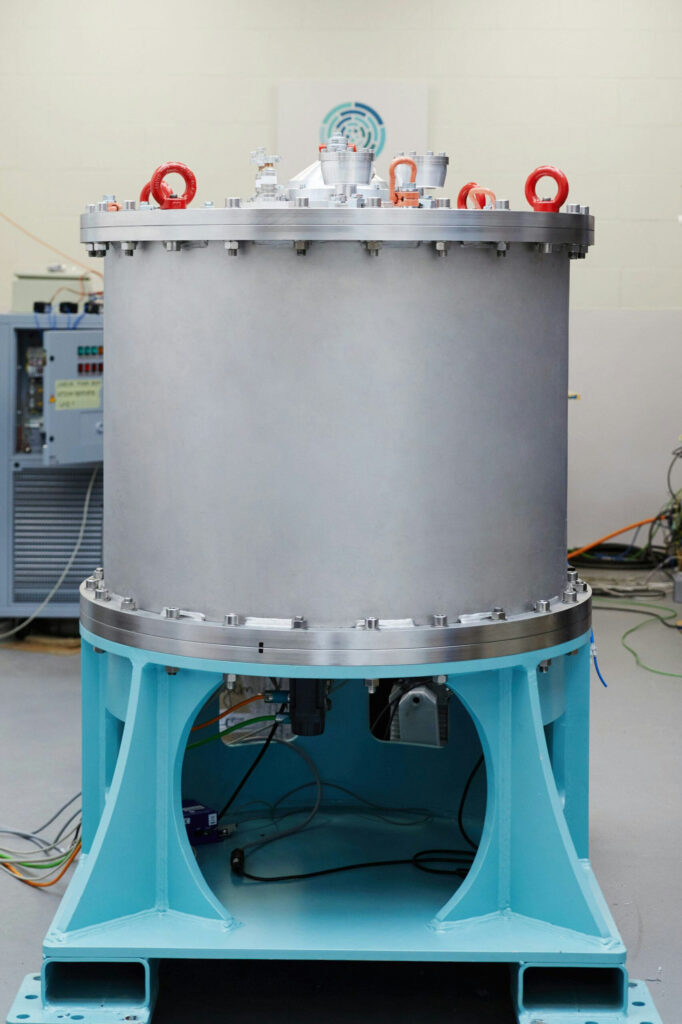

It’s easy to overlook QuinteQ’s office. Nothing about the warehouse on a generic business park in Culemborg hints that the future is being worked on inside. Even inside, the presence of a 20-ft container, a few shelves, and a tangle of power cables doesn’t exactly scream energy revolution. It all looks quite ordinary—but it’s not. Standing in the middle of the hall is the QuinteQ flywheel: a large metal drum on a pedestal, with cables and pipes, delivering energy in a way that’s never been done before in construction.

“This flywheel was developed by aircraft manufacturer Boeing,” says Timo Pauel, Business Development Manager at QuinteQ. “It’s the most advanced flywheel in the world, originally intended for aerospace use. But we also see potential in using this ‘kinetic battery’ for absorbing peak loads on construction sites, known as peak shaving.” That’s why QuinteQ partnered with BAM, which used the flywheel on a construction site in Amsterdam this past December.

Metal drum

First, the basic principle: a flywheel can store energy, just like a battery—but not through chemical processes, but through motion. The QuinteQ flywheel is essentially a metal drum containing a carbon-fiber rotor. This rotor is spun up to 22,000 revolutions per minute using a motor-generator powered by electricity from a grid connection. It takes only a few minutes to reach this speed, at which point the “kinetic battery” is fully charged.

The same motor-generator can then slow the flywheel down, converting the released energy into electricity. If that’s hard to visualize, think of an old-fashioned bicycle dynamo pressed against a spinning wheel. But instead of flickering lights, this flywheel can deliver short, intense power bursts—exactly what’s needed for large construction cranes, like those BAM uses in Amsterdam’s Sluisbuurt, where nearly 800 student apartments are being built. Just the cranes alone require more than 3x80A in power.

“A construction project has to run on a site connection,” explains Pauel, “but with today’s grid congestion, it’s difficult to get a large enough connection to power your tower crane.”

Working with flywheel technology

It sounds simple, but there are quite a few requirements to work safely and efficiently with flywheel technology. Traditionally, flywheels are heavy, which leads to significant efficiency losses due to friction and air resistance. That’s one reason flywheel technology never really took off in Formula 1: in the event of an accident, a detached flywheel could have catastrophic consequences. On top of that, in mobile applications, the gyroscopic effect of a heavy flywheel introduces another unwanted behavior, officially called ‘precession’.

In daily life, you can see this by spinning a bicycle wheel and holding it at one axis—it stays upright on its own. But in scenarios like race cars or city buses (where the tech has also been tested), this effect can negatively affect cornering. For stationary applications like construction sites, only the first issue applies, which is why flywheels are often placed underground in a container for safety reasons.

“The energy loss is very low, about 0.1% per hour” – Wouter Biemans

The QuinteQ flywheel stands out due to its relatively low weight, which significantly reduces risk. Wouter Biemans, Chief Technical Officer at QuinteQ, gives a quick physics lesson: “The energy density of a flywheel increases linearly with mass and quadratically with rotational speed. In other words, you can store more energy in a small, lightweight, fast-spinning flywheel than in a heavy one. So, we prioritized speed over weight.” To achieve this, QuinteQ uses frictionless magnetic bearings and places the flywheel in a vacuum-sealed chamber to eliminate air resistance. Biemans: “The energy loss is very low, about 0.1% per hour.”

Peak loads

Flywheels are best suited for applications where power is more important than energy. A major advantage of kinetic energy storage over chemical batteries is that there’s no degradation. Pauel explains: “Construction cranes demand frequent, high power peaks lasting seconds to a few minutes. If you use lithium batteries for that, you wear them out quickly. That’s not an issue with a flywheel—there’s virtually no wear and tear.”

QuinteQ claims a lifespan of over 30 years and 350,000 charge cycles. Pauel adds: “The upper limit is hard to determine. It could even be over a million cycles. That’s because we have a frictionless flywheel, and the large components last extremely long. Plus, all the materials we use are highly recyclable. This tech fits well with the energy transition.”

Another major advantage of kinetic energy storage is the much lower safety risk. “Lithium batteries can catch fire if overcharged or damaged. On a construction site with dust, water, and flammable materials, that risk is real. Moreover, the materials needed to produce lithium batteries are scarce, and their extraction is far from sustainable.”

Further development

Thanks to the Clean and Emission-Free Construction Equipment Subsidy Scheme (SSEB), more research into the development of the flywheel is possible. “We’re still working with a prototype,” says Pauel. “Thanks to our collaboration with BAM and crane rental company Van der Spek, we’re gaining better insight into how this technology can be used.” Van der Spek provides QuinteQ with measurement data from its tower cranes, enabling extra analysis and simulations.

What QuinteQ already knows is that the flywheel system can be more compact. “Just look,” Pauel says, pointing to the half-filled 20-ft container housing the electronics. “We’ve got plenty of space left. For series production, we’ll use 10-ft containers instead. The smaller, the better.”

“At BAM, they believe every technology—including flywheel technology—has a place in the energy transition” – Timo Pauel

QuinteQ expects to begin production of the flywheel in the second half of 2024. “This isn’t a race to come up with the ‘best’ solution. Our product is particularly well-suited for this specific energy demand. Other applications will need other solutions. At BAM, they believe every technology—including flywheel technology—has a place in the energy transition,” Pauel concludes.

Once again, we appreciate Mischa Bijenhof and Bouwmachines for covering QuinteQ’s flywheel energy storage system.

Have any questions about how our flywheels work? Send us an email at info@quinteqenergy.com, or send us a message through our LinkedIn!